Completely customized according to different customer needs

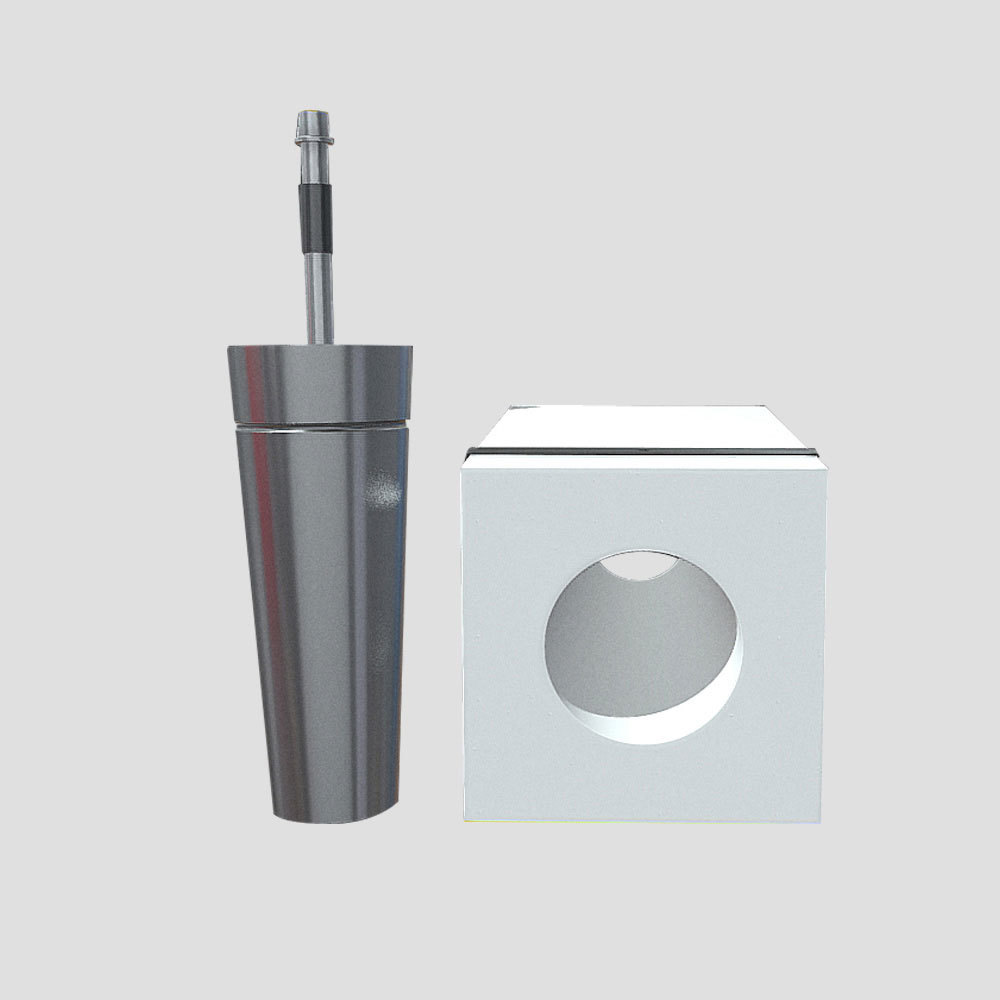

Contact UsThis product is made of high-purity raw materials, and fired at high temperatures. It has the advantage of excellent thermal shock resistance and erosion resistance, and good anti-infiltration ability. It consists of a well block and an anti-infiltration purging plug core, which consists of anti-infiltration breathable component, security alert, and sealing components. The product supplies argon gas through anti-infiltration breathable component, and is used in the argon blowing process of LF, LF-VD, CAS-OB refined ladle and continuous casting ordinary ladle. It needs less cleaning or even no cleaning, and is durable and safe. Compared to slit-type purging plug, it is safer, saves energy and reduces emissions, and therefore reduces cost and increase efficiency for customers.

This product is made of high-purity raw materials, molded through vibration, and processed under low-temperature thermal treatment. The product supplies argon gas through the slits on purging plug core, which has the advantages of high thermal strength, excellent thermal shock resistance and erosion resistance. Its performance has reached or exceeded similar imported products, and is used in the argon blowing process of LF, LF-VD, CAS-OB refined ladle and continuous casting ordinary ladle in steel mills, with long service life, high blow-through rate and good safety. The product is used in Sha-steel, Nan-Gang, Lianfeng-steel, Tang-steel, Ben-steel and Longteng special steel, and has been well received by customers.

This product is made of high-purity raw materials, molded through vibration, and processed under low-temperature thermal treatment. The product supplies argon gas through the slits on purging plug core, which has the advantages of high thermal strength, excellent thermal shock resistance and erosion resistance. Its performance has reached or exceeded similar imported products, and is used in the argon blowing process of LF, LF-VD, CAS-OB refined ladle and continuous casting ordinary ladle in steel mills, with long service life, high blow-through rate and good safety. The product is used in Sha-steel, Nan-Gang, Lianfeng-steel, Tang-steel, Ben-steel and Longteng special steel, and has been well received by customers.

This product is made of high-purity raw materials, molded through vibration, and baked under low-temperature.

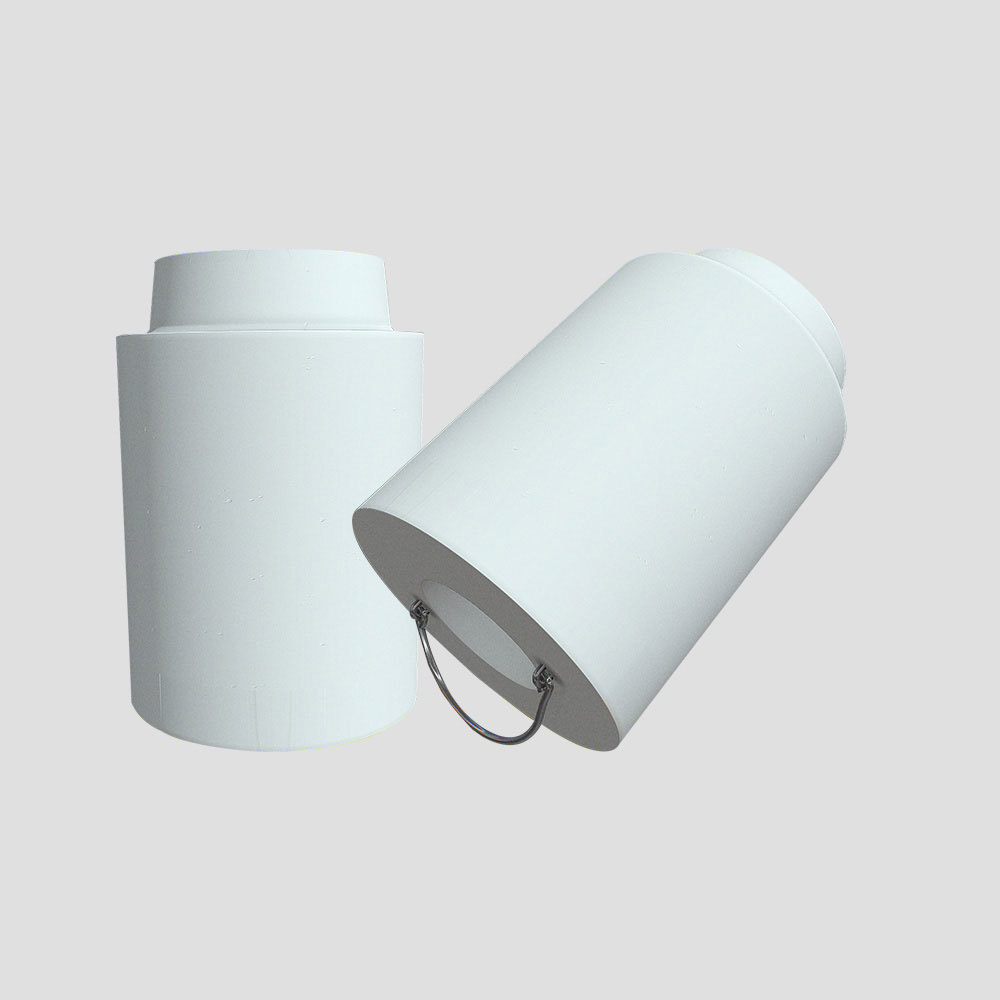

Split purging plug consists of slit-type or anti-infiltration purging plug core, well block and high-quality mortar, all of which could be purchased separately. Its flexibility meets the requirements of different refining conditions, and it is used in the argon blowing process of LF, LF-VD, CAS-OB refined ladle and continuous casting ordinary ladle. The high-quality mortar is made of high-purity corundum and many additives. Customers only need to add water before use. It has the advantage of high refractoriness, easy to blend, high bond strength, good safety and easy dissociation.

Magnesium oxide castables are widely used in refining ladles due to their advantages such as fast construction, labor saving and better slag resistance. However, the performance of on-site castables is greatly affected by factors such as temperature, PH value, hardness, casting time, vibration intensity, maintenance time and drying time. In order to solve this problem, we have developed carbonless precast blocks with the following advantages: short installation time, no need for large mixers and molding equipment, no need for skilled installation procedures, short drying time compared to castables, suitable for quick turnaround of ladles, no explosive flaking, no thermal flaking, and better slag resistance.

The upper/down nozzle are mainly made of sintered corundum, fused corundum, fused mullite, and other raw materials.

The upper/down nozzle are mainly made of sintered corundum, fused corundum, fused mullite, and other raw materials.

This product has been developed to meet the demand for production of low-carbon and ultra-low-carbon steel. In contrast to carbonless prefabricated blocks, the developed product is formed by friction press molding, so we can easily customize the required bricks (with or without carbon) and can meet a wide variety of service conditions.

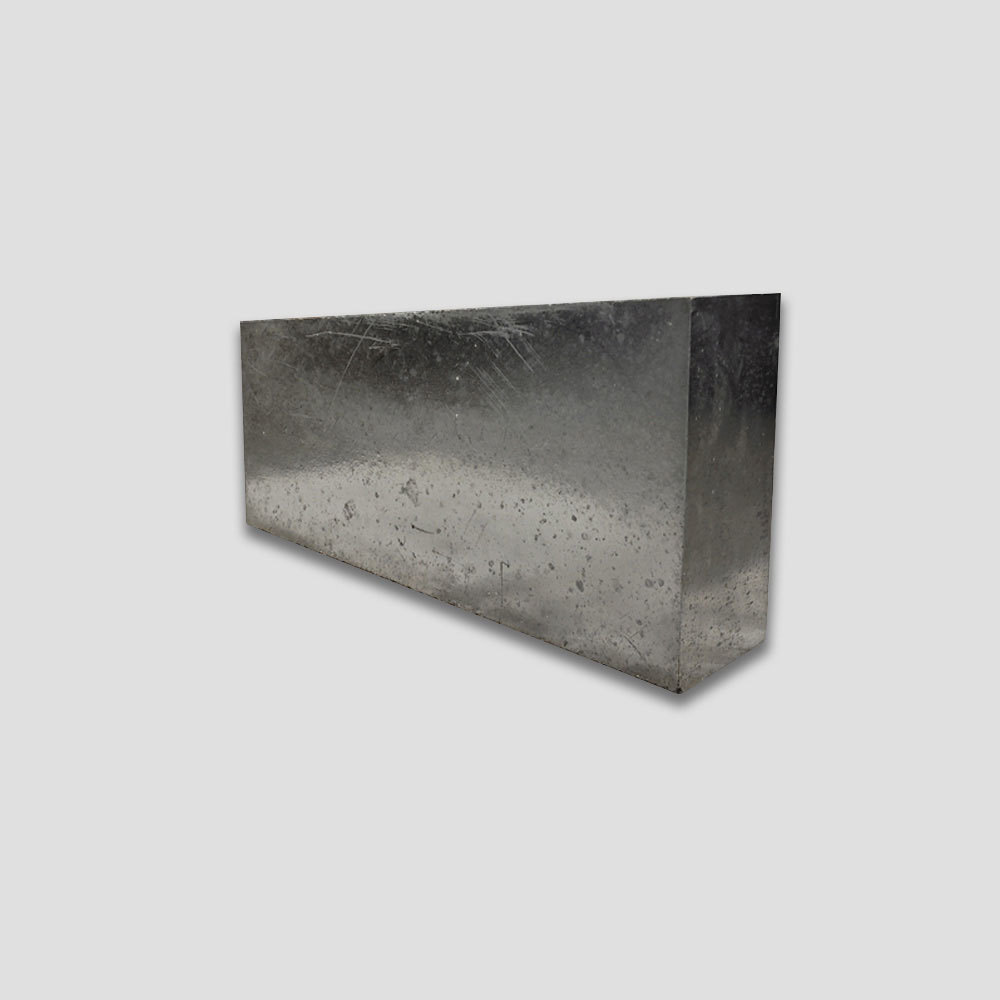

The ladle bottom magnesia carbon brick is made of EAF magnesia and flake graphite as the main raw materials, adding an appropriate amount of antioxidants, and phenolic resin as a binding agent through high pressure molding, which has excellent erosion resistance and thermal shock stability.

The ladle slag line magnesia carbon brick has the characteristics of strong slag erosion resistance, erosion resistance, and thermal shock stability.

This product is mainly made of tabular corundum, fused corundum, zirconia corundum, zirconia mullite, and other raw materials. By adding an appropriate amount of metal micro and fine powder through high-temperature reaction, the high-temperature performance of the slide gate is improved. An appropriate amount of micro powder such as boron carbide is added to improve the oxidation resistance. Phenolic resin with high solid content and high residual carbon is used as a binder, which is high-pressure formed by a press and processed at an appropriate temperature.