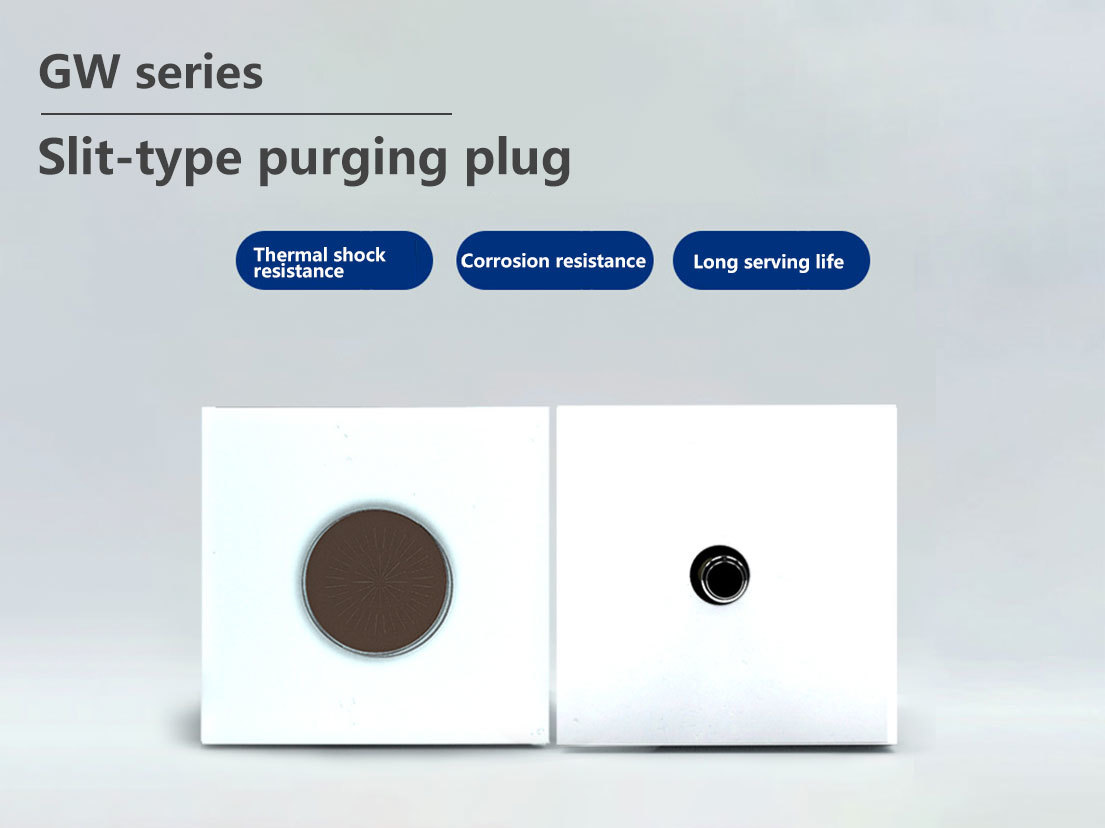

GW Series Slit-type Purging Plug

This product is made of high-purity raw materials, molded through vibration, and processed under low-temperature thermal treatment. The product supplies argon gas through the slits on purging plug core, which has the advantages of high thermal strength, excellent thermal shock resistance and erosion resistance. Its performance has reached or exceeded similar imported products, and is used in the argon blowing process of LF, LF-VD, CAS-OB refined ladle and continuous casting ordinary ladle in steel mills, with long service life, high blow-through rate and good safety. The product is used in Sha-steel, Nan-Gang, Lianfeng-steel, Tang-steel, Ben-steel and Longteng special steel, and has been well received by customers.

Category:

Main Components:

Corundum spinel

Al₂O₃ : 90-95%

MgO: 0-3.5%

Cr₂O₃: 0-3%

Main Components: Corundum spinel

90-95%

0-3.5%

keyword: GW Series Slit-type Purging Plug

Features

Production And Development

Focus on production and development of functional refractories for 22 years

Patents For Invention

Insist on developing new products, improving technology and strengtening know-how

Intellectual Property Right

27 utility model independent intellectual properties

Cooperative Partners

Provide solutions for 40 Iron and Steel Groups Excellent product supplier

Indicators

Item | Gas Permeable Brick | Seat Brick |

Bulk Density(g/cm3) | ≥3.2 | ≥3.2 |

Flexural Strength(110°Cx24h,MPa) | ≥5.0 | ≥8.0 |

Flexural Strength(1550°Cx3h,MPa) | ≥25.0 | ≥20.0 |

C.C.S.(110°Cx24h,MPa) | ≥35.0 | ≥55.0 |

C.C.S.(1550°Cx3h,MPa) | ≥130.0 | ≥120.0 |

Al2O3(%) | 90~96 | / |

MgO(%) | 1.5~3.0 | / |

CaO(%) | 0.8~2.6 | / |

Cr2O3(%) | 0~3.0 | / |

Al2O3+MgO(%) | / | ≥90.0 |

Model

Production Site

Automatic mixing system

The ingredient production capacity is 30000 tons per year, mainly composed of material silos, ingredient carts, dust removal systems, etc. This system has advantages such as high production efficiency and environmental friendliness.

Tunnel Kiln

It consists of the kiln foundation, kiln body, natural gas heating system, preheating utilization, kiln car transportation system, hot air circulation system, flue gas treatment system, and automatic control system. Can meet the demand for an annual production capacity of 10000 tons.

Partners

FAQ

Q

How to place an order?

A

Q

What is the minimum order quantity for your company?

A

Q

What are the packaging conditions of your company?

A

Q

What is your company's sample policy?

A

Q

Can your company produce based on the sample?

A

Q

What are your company's delivery terms? How long is the delivery time?

A

Q

Will your company provide a price list?

A

Q

Can you obtain more detailed information about your company and products?

A

Q

How long is the validity period of the quotation?

A

Q

Does your company welcome customers to visit your company?

A

Related products

The graphite crucible is applied for cathode for lithium battery, which maintain the chemical structure stability in the high temperature evaporation and reaction container. The crucible is comprised of silicon carbide, high purity graphite therefore its thermal shock property is excellent. Thanks to the high content of silicon carbide, this materials is anti-oxident, corrosion resistant and acid resistant.

The graphite crucible is applied for cathode for lithium battery, which maintain the chemical structure stability in the high temperature evaporation and reaction container. The crucible is comprised of silicon carbide, high purity graphite therefore its thermal shock property is excellent. Thanks to the high content of silicon carbide, this materials is anti-oxident, corrosion resistant and acid resistant.

This product is made of high-purity raw materials, and fired at high temperatures. It has the advantage of excellent thermal shock resistance and erosion resistance, and good anti-infiltration ability. It consists of a well block and an anti-infiltration purging plug core, which consists of anti-infiltration breathable component, security alert, and sealing components. The product supplies argon gas through anti-infiltration breathable component, and is used in the argon blowing process of LF, LF-VD, CAS-OB refined ladle and continuous casting ordinary ladle. It needs less cleaning or even no cleaning, and is durable and safe. Compared to slit-type purging plug, it is safer, saves energy and reduces emissions, and therefore reduces cost and increase efficiency for customers.

This product is made of high-purity raw materials, molded through vibration, and processed under low-temperature thermal treatment. The product supplies argon gas through the slits on purging plug core, which has the advantages of high thermal strength, excellent thermal shock resistance and erosion resistance. Its performance has reached or exceeded similar imported products, and is used in the argon blowing process of LF, LF-VD, CAS-OB refined ladle and continuous casting ordinary ladle in steel mills, with long service life, high blow-through rate and good safety. The product is used in Sha-steel, Nan-Gang, Lianfeng-steel, Tang-steel, Ben-steel and Longteng special steel, and has been well received by customers.

Speak To One of Our Experts

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!