Completely customized according to different customer needs

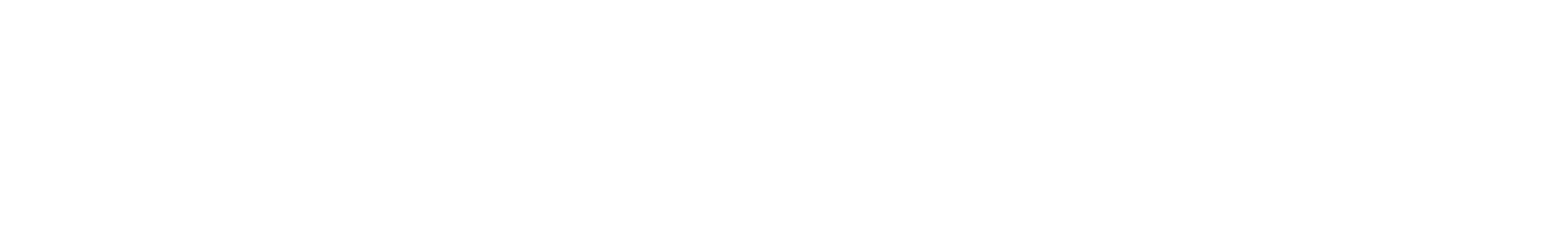

Contact UsMagnesium oxide castables are widely used in refining ladles due to their advantages such as fast construction, labor saving and better slag resistance. However, the performance of on-site castables is greatly affected by factors such as temperature, PH value, hardness, casting time, vibration intensity, maintenance time and drying time. In order to solve this problem, we have developed carbonless precast blocks with the following advantages: short installation time, no need for large mixers and molding equipment, no need for skilled installation procedures, short drying time compared to castables, suitable for quick turnaround of ladles, no explosive flaking, no thermal flaking, and better slag resistance.

This product has been developed to meet the demand for production of low-carbon and ultra-low-carbon steel. In contrast to carbonless prefabricated blocks, the developed product is formed by friction press molding, so we can easily customize the required bricks (with or without carbon) and can meet a wide variety of service conditions.

The ladle bottom magnesia carbon brick is made of EAF magnesia and flake graphite as the main raw materials, adding an appropriate amount of antioxidants, and phenolic resin as a binding agent through high pressure molding, which has excellent erosion resistance and thermal shock stability.

The ladle slag line magnesia carbon brick has the characteristics of strong slag erosion resistance, erosion resistance, and thermal shock stability.

Block mending material targets to fill into concave or spray onto ladle defects. By well mixing the mending mixture by adding water in certain mixing ratio, the mending process include mixing, spreading or spraying and hardening. It meets with different applications. Similar as castable, block mending material endure the high temperature during the application. Therefore strictly control the water content is critical to the engineering mending.

This product is produced using high-purity raw materials of the same material as the well block, and has performance comparable to the well block. It is used in the purging plug replacement for LF, LF-VD, CAS-OB refined steel ladles and continuous casting ordinary steel ladles, or mending for sliding nozzle well block. It has good bonding performance, excellent erosion resistance, long service life, and is easy to operate.

The castable is made of alumina spinel, calcium which are bonded together.

Ladle bottom containing the blend of materials that formed initially from binding the corundum and sinter form of magnesium alumina spinel into a pre-casting. The binder is used in form of particles or fused materials, like magnesium, corundum and micro powder as additives.