Completely customized according to different customer needs

Contact UsThe upper/down nozzle are mainly made of sintered corundum, fused corundum, fused mullite, and other raw materials.

This product has been developed to meet the demand for production of low-carbon and ultra-low-carbon steel. In contrast to carbonless prefabricated blocks, the developed product is formed by friction press molding, so we can easily customize the required bricks (with or without carbon) and can meet a wide variety of service conditions.

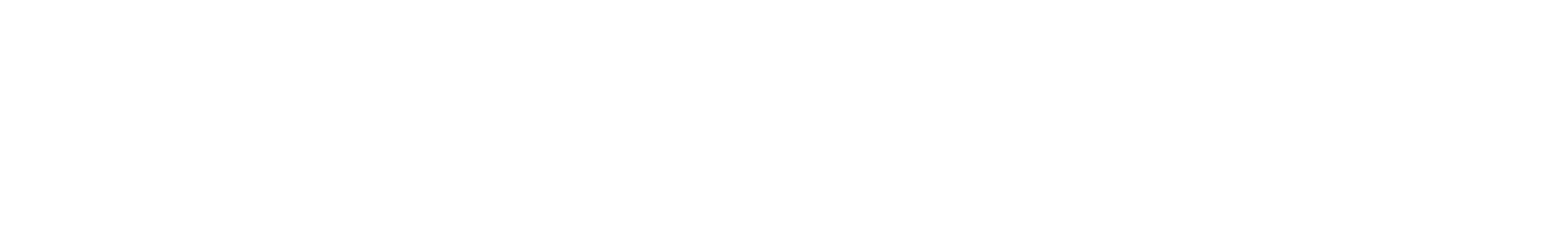

The ladle bottom magnesia carbon brick is made of EAF magnesia and flake graphite as the main raw materials, adding an appropriate amount of antioxidants, and phenolic resin as a binding agent through high pressure molding, which has excellent erosion resistance and thermal shock stability.

The ladle slag line magnesia carbon brick has the characteristics of strong slag erosion resistance, erosion resistance, and thermal shock stability.

EAF magnesia carbon brick is made of capacitive magnesia and high-carbon graphite as the main raw materials, adding an appropriate amount of antioxidant, and using phenolic resin as a binding agent through high-pressure molding. The products have excellent erosion resistance and thermal shock stability, and are widely used in electric arc furnaces.

This product is mainly made of tabular corundum, fused corundum, zirconia corundum, zirconia mullite, and other raw materials. By adding an appropriate amount of metal micro and fine powder through high-temperature reaction, the high-temperature performance of the slide gate is improved. An appropriate amount of micro powder such as boron carbide is added to improve the oxidation resistance. Phenolic resin with high solid content and high residual carbon is used as a binder, which is high-pressure formed by a press and processed at an appropriate temperature.

The tundish prefabricated components include slag wall, slag weir, impact pad and flow straightener, etc., which are made of magnesia, bauxite, white corundum, etc. as the main raw materials, combined with micro powder and superfine powder, mixed with coagulant and dispersant, preformed, and baked at medium temperature. It is suitable for continuous casting tundish, and prefabricated with different lifetime and materials according to the different smelting requirements of customers. The product is used in Guangzhou Lianzhong Stainless Steel Co., Ltd. and other companies, and has been well received by customers.

The tundish prefabricated components include slag wall, slag weir, impact pad and flow straightener, etc., which are made of magnesia, bauxite, white corundum, etc. as the main raw materials, combined with micro powder and superfine powder, mixed with coagulant and dispersant, preformed, and baked at medium temperature. It is suitable for continuous casting tundish, and prefabricated with different lifetime and materials according to the different smelting requirements of customers. The product is used in Guangzhou Lianzhong Stainless Steel Co., Ltd. and other companies, and has been well received by customers.

Block mending material targets to fill into concave or spray onto ladle defects. By well mixing the mending mixture by adding water in certain mixing ratio, the mending process include mixing, spreading or spraying and hardening. It meets with different applications. Similar as castable, block mending material endure the high temperature during the application. Therefore strictly control the water content is critical to the engineering mending.

This product has characteristics such as low thermal conductivity and strong impermeability, making is quick and convenient to construct. It is used as an impermeable layer at the bottom of aluminum electrolytic cells.

This product is produced using high-purity raw materials of the same material as the well block, and has performance comparable to the well block. It is used in the purging plug replacement for LF, LF-VD, CAS-OB refined steel ladles and continuous casting ordinary steel ladles, or mending for sliding nozzle well block. It has good bonding performance, excellent erosion resistance, long service life, and is easy to operate.

The product is a SiC castable developed by using high-purity SiC as the main material, pure calcium aluminate cement and micro-powder as a binder. It has high temperature strength and wear resistance, and can be casted, sprayed and smeared. It can be used in garbage incinerators, blast furnace bodies, cyclone furnaces, boiling furnaces and boilers and other wear-prone parts, and can also be used as high thermal conductivity refractories.